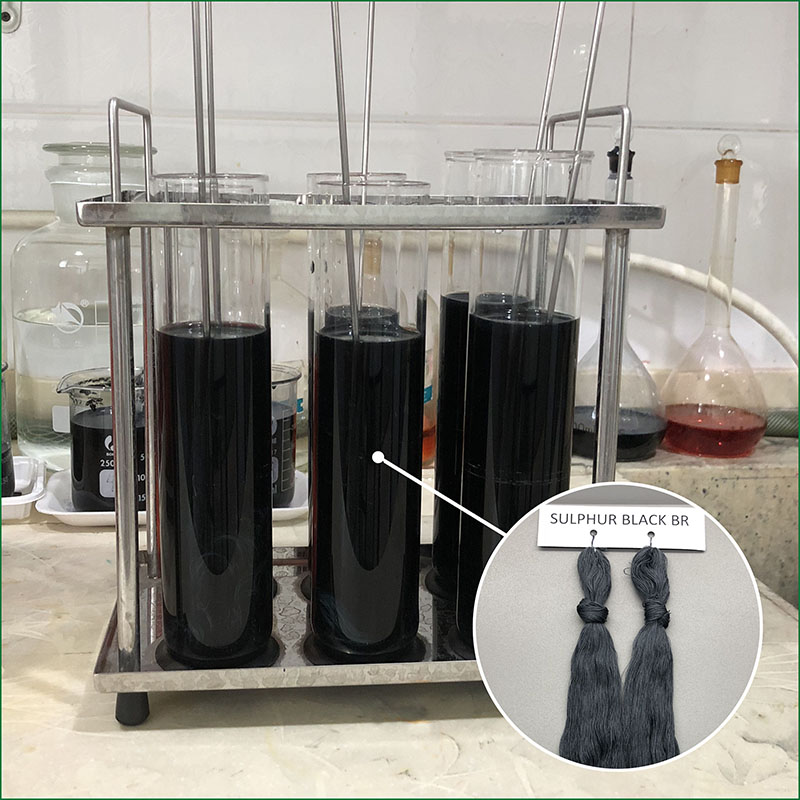

Understanding Sulphur Black Dye in Textile Industry

Sulphur black dye stands as a fundamental component in textile dyeing processes, predominantly utilized for imparting rich colors to cotton fibers. Sulphur black applications, though diverse, follow a standard set of specifications and a meticulous dyeing procedure, distinguishing its significance in the textile domain.

Specifications of Sulphur Black Dye:

- Chemical Composition: Sulphur black dyes, belonging to the sulfur dye class, primarily consist of sulfur-based compounds.

- Color and Strength: Renowned for their deep, nearly black hue, these dyes come in varied strengths or concentrations, typically indicated by active dye content percentages. Higher concentrations imply stronger dyes that demand lesser quantity for optimal dyeing.

- Solubility and Fastness Properties: Their insolubility in water necessitates a reduction process to render them soluble. However, they showcase excellent color fastness to washing and light, ensuring durability against fading or bleeding.

- Moisture Content and Impurities: Specifications may include moisture content limits and impurity thresholds (such as ash content or insoluble matter) to maintain dye quality and handling.

- pH Sensitivity and Application Methods: Some formulations may indicate pH ranges for optimal dye performance, alongside recommended application methods, temperatures, and durations.

Dyeing Process with Sulphur Black:

The application process involves meticulous steps of sulphur black:

- Reduction Process: Insoluble in water initially, the dye undergoes a reduction process, transforming it into a water-soluble form, termed leuco sulphur, through treatment with sodium sulfide or sodium hydrosulfite in an alkaline solution.

- Dye Bath Preparation and Dyeing: The leuco sulphur dye solution, prepared by dissolving the reduced dye in water with specific additives, hosts the fabric (often cotton) during dyeing, carried out at elevated temperatures for several hours.

- After-Treatment and Finishing: Post-dyeing, thorough rinsing, chemical treatment, and washing eliminate excess dye and enhance color fastness. Further finishing processes, including drying and pressing, ascertain desired fabric properties.

The Significance of Sulphur Black Dye:

- Cost-effectiveness: Its economical nature deems it ideal for bulk cotton fabric dyeing.

- Color Diversity and Stability: Renowned for producing deep, sought-after dark shades, while exhibiting robust color fastness against washing and light exposure.

- Cotton Compatibility and Versatility: Its affinity for cotton fibers ensures widespread use across various cotton textile applications, from garments to industrial fabrics.

- Global Availability and Environmental Considerations: Widely manufactured worldwide, advancements in production techniques strive for more environmentally friendly processes, contributing to its widespread adoption.

In conclusion, sulphur black dye’s blend of cost-effectiveness, color range, and color fastness renders it a cornerstone in the textile industry, especially for dyeing cotton fibers. Visit news website for more technology news.